GE Security offers reliable alarm systems with advanced features, ensuring home and business protection. Their systems include zone management, event logging, and user-friendly interfaces for optimal security control.

Overview of GE Security Alarm Manual

The GE Security Alarm Manual is a comprehensive guide designed to help users understand, install, and operate their security systems effectively. It provides detailed instructions for configuring zones, troubleshooting common issues, and utilizing advanced features. The manual covers essential topics such as arming/disarming procedures, event logging, and system customization. Additionally, it includes sections on panic buttons, emergency alarms, and integration with other devices. This resource ensures users can maximize their system’s potential while maintaining security and efficiency. By following the manual, users can resolve errors, update software, and perform regular maintenance to keep their system running smoothly.

System Features and Capabilities

GE Security systems offer advanced features like zone management, event logging, and customizable alarms. They provide robust protection with user-friendly interfaces for seamless control and monitoring.

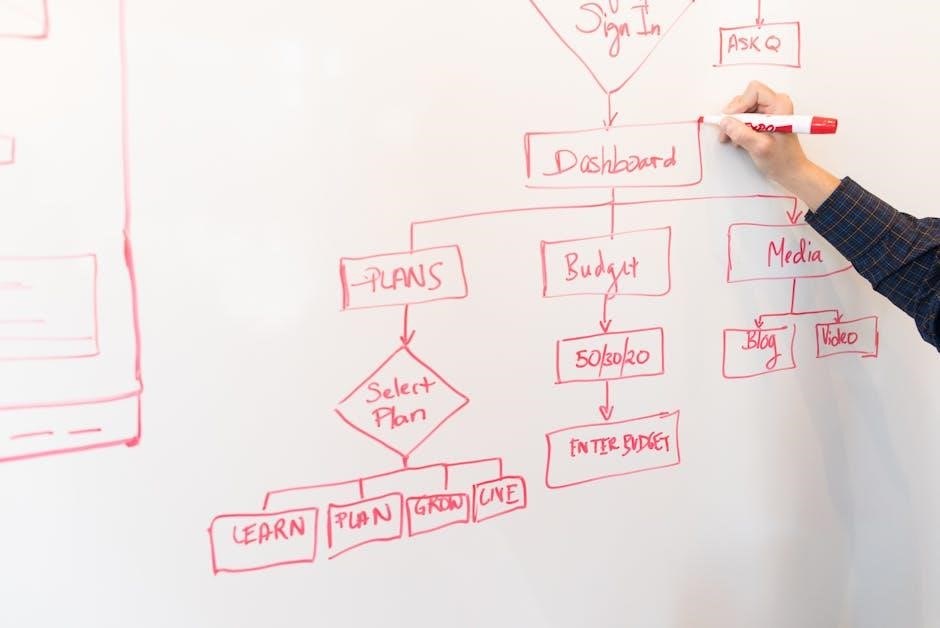

Zone Configuration and Management

Zone configuration is a critical feature in GE Security systems, allowing users to customize protection for specific areas. Each zone can be assigned to doors, windows, or motion detectors, ensuring tailored security. The system supports multiple zones, which can be programmed for different responses, such as triggering alarms or sending notifications. Sensitivity adjustments enable fine-tuning for motion detectors to minimize false alarms. The NX-148 model, for instance, offers advanced zone management with LED indicators for status monitoring. This feature enhances flexibility, ensuring optimal protection while reducing unnecessary alerts. Proper zone configuration is essential for maximizing system efficiency and user convenience.

Alarm Memory and Event Logging

The GE Security system features robust alarm memory and event logging capabilities, ensuring detailed tracking of security incidents. The NX-148 model records alarm events, including zone activations and system arming/disarming. This data helps users analyze patterns and respond to threats effectively. Event logs are stored securely, providing a tamper-proof record of all system activities. Users can review these logs to identify potential issues or breaches. This feature is crucial for maintaining system integrity and enhancing security measures. Regular review of alarm memory and event logs ensures proactive monitoring and timely resolution of security concerns. This capability is essential for both residential and commercial setups.

Installation and Setup

GE Security systems require careful hardware installation and software configuration, including sensor connections and programming settings, to ensure proper functionality and optimal security performance.

Hardware Installation Requirements

Proper installation of GE Security systems requires careful planning and execution. Begin by ensuring all necessary components, such as control panels, sensors, and wiring, are available. Install sensors in strategic locations to maximize coverage, following the manufacturer’s guidelines for placement and alignment. Connect wiring securely, avoiding interference sources to maintain signal integrity. Ensure the control panel is mounted in an accessible location, and power supplies are correctly installed. Test all zones and devices post-installation to verify functionality. Refer to the manual for specific torque specifications and mounting instructions to prevent damage. Finally, conduct a system test to ensure all hardware operates seamlessly.

Software Configuration and Programming

Software configuration for GE Security systems involves setting up user codes, zone definitions, and system parameters. Begin by accessing the control panel’s programming mode, typically using a master code. Define zones by assigning sensors to specific areas, ensuring each zone is labeled clearly for easy identification. Set up user codes with varying access levels, such as administrative or basic user rights. Configure alarm response settings, including delay times and notification preferences. Integrate with smart devices if compatible, enabling remote monitoring and control. Review and test all programmed settings to ensure functionality. Refer to the manual for detailed instructions on advanced features like custom scenarios or automation rules;

Arming and Disarming the System

GE Security systems offer three arming levels: Off (Disarm Mode), Armed (Perimeter Protection), and Fully Armed (Total Protection). Each level provides varying degrees of security coverage.

Level 1 ー Off (Disarm Mode)

Level 1, or Off mode, disables all security features, allowing unrestricted access to the premises. This mode is used to cancel active alarms, stop sirens, and disarm the system. When activated, it ensures the system does not trigger alarms, providing a safe entry or exit. Users can enter this mode by inputting their access code, ensuring authorized access only. This level is essential for routine activities or when no protection is needed. It restores full system functionality once exited, preparing the system for rearming when required.

Level 2 ー Armed (Perimeter Protection)

Level 2 activates perimeter protection, monitoring external doors and windows while allowing free movement inside. Sensors detect breaches, triggering alarms and alerts. Suitable for nighttime or when occupants are inside, this mode ensures early detection of unauthorized access. It arms boundary zones, providing a secure barrier against intruders. The system remains vigilant, ready to respond to potential threats while maintaining convenience for those inside. This level offers a balanced security approach, ideal for active protection without restricting internal activities.

Level 3 ー Fully Armed (Total Protection)

Level 3 provides maximum security by arming all zones, both internal and external. This mode ensures complete protection, ideal for when the premises are unoccupied. Motion detectors and door/window sensors are fully active, triggering alarms instantly upon unauthorized entry. The system alerts users and monitoring centers, ensuring rapid response. Level 3 is designed for high-security situations, offering total coverage and peace of mind. It minimizes false alarms while maintaining heightened vigilance, making it perfect for overnight or extended periods of absence. The system remains on high alert, safeguarding against any potential threats.

Understanding Alarm Zones

Alarm zones divide your space into monitored areas, each triggering alerts for specific breaches, helping pinpoint threats and enhancing security customization for tailored protection needs effectively.

Zone Types and Assignments

Zone types in GE Security systems are categorized to monitor specific areas, such as perimeter zones for exterior protection or interior zones for internal spaces. Each zone can be programmed to detect unique conditions, ensuring tailored security responses. Assignments involve designating sensors or devices to zones, enabling precise control over alarm triggers and notifications. This customization allows users to prioritize certain areas or define emergency zones for critical events. Proper zone configuration enhances system efficiency, ensuring alerts are relevant and actionable, while reducing false alarms.

Zone Sensitivity and Adjustments

Zone sensitivity in GE Security systems can be tailored to minimize false alarms while ensuring accurate detection. Adjustments are made via the control panel or programming software, allowing users to fine-tune sensor thresholds. High-traffic areas may require lower sensitivity to avoid triggers from normal activity, while critical zones benefit from higher sensitivity. The system’s manual provides detailed steps for calibration, ensuring optimal performance. Regular sensitivity checks are recommended to maintain reliability and adapt to environmental changes, such as seasonal variations or new furniture layouts. Proper adjustments enhance system effectiveness and user confidence in alarm responses.

Troubleshooting Common Issues

Identify and resolve common problems like false alarms or system errors by checking sensors, reviewing event logs, and ensuring proper zone configurations. Refer to the manual for solutions.

Alarm False Triggers and Solutions

False triggers occur due to sensor sensitivity or environmental factors like dust or pets. Adjust sensor settings, clean detectors, and ensure proper zone configuration to minimize false alarms. Regular maintenance and software updates also help prevent unwanted activations. Refer to the manual for detailed troubleshooting steps and solutions to enhance system reliability and reduce false triggers effectively.

System Error Codes and Diagnostics

GE Security systems display error codes to identify issues, such as sensor malfunctions or communication failures. Codes like E01 or E02 indicate specific problems, guiding users to solutions. The manual provides detailed diagnostics for each code, enabling quick troubleshooting. Regular system checks and software updates help prevent errors. If issues persist, resetting the system or consulting the manual is recommended. Understanding these codes ensures optimal performance and security. Always refer to the manual for specific error resolutions and maintenance tips to keep your system running smoothly and reliably.

Advanced Features and Customization

GE Security systems offer panic buttons for emergencies and integration with smart devices for enhanced functionality. Users can customize settings to tailor security solutions to their needs.

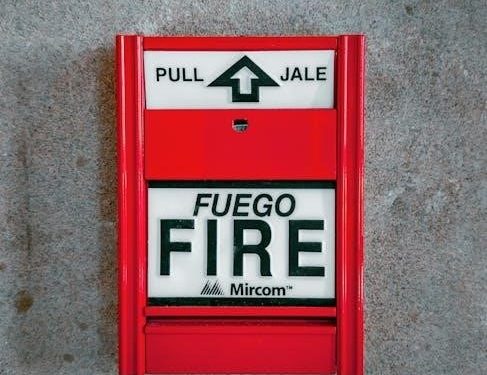

Panic Buttons and Emergency Alarms

Panic buttons in GE Security systems enable immediate emergency response. When pressed for two seconds, they trigger alarms and notify monitoring services. This feature ensures quick action during critical situations, providing an additional layer of safety for users. The system’s emergency alarms are designed to alert both occupants and authorities, ensuring a swift response. These buttons are strategically placed for easy access, offering peace of mind and reliable protection in high-stress scenarios. Their integration with the overall security setup enhances the system’s effectiveness in safeguarding lives and property effectively and efficiently.

System Integration with Other Devices

GE Security systems seamlessly integrate with various devices, enhancing overall security management. Compatibility with products like WorkstationST Alarm Viewer and CADDX systems ensures comprehensive monitoring. The system supports third-party integrations, allowing synchronization with smoke detectors, cameras, and access control panels. This unified approach streamlines security operations, enabling real-time monitoring and efficient response. Integration capabilities also extend to remote access, enabling dealers to perform diagnostics and updates. By connecting multiple devices, GE Security systems provide a robust, interconnected solution for advanced protection and convenience, ensuring all components work harmoniously to safeguard premises effectively.

Maintenance and Upkeep

Regular system checks, battery replacements, and software updates are crucial for optimal performance. Ensure all components are inspected periodically to maintain reliability and security effectiveness.

Regular System Checks and Updates

Performing regular system checks ensures all components function optimally. Users should test sensors, check wiring, and verify communication links. Software updates are essential for security patches and feature enhancements, maintaining system reliability and performance. Schedule periodic inspections to identify and address potential issues before they escalate. This proactive approach guarantees uninterrupted protection and peace of mind.

Battery Replacement and Power Management

Regular battery checks are crucial for system reliability. Replace batteries every 3-5 years or when the system indicates low power. Use high-quality, compatible batteries to ensure optimal performance. Avoid mixing old and new batteries, as this can reduce efficiency. Additionally, ensure all power connections are secure and free from damage. Backup power systems, like batteries, should be tested during outages to confirm functionality. Proper power management extends system lifespan and prevents unexpected failures, ensuring continuous protection and peace of mind.

The GE Security Alarm System provides comprehensive protection with advanced features and user-friendly operation. By adhering to the manual’s guidelines, users can ensure optimal performance and reliability. Regular system checks, updates, and proper battery management are essential for maintaining security. Understanding the system’s capabilities and customization options empowers users to tailor their security needs effectively. Whether for residential or commercial use, GE Security systems offer peace of mind through robust protection and intuitive control.