Julia Alvarez’s novel explores the García sisters’ journey of cultural identity, blending humor and poignancy as they navigate their Dominican heritage and American life, resonating universally.

Background of the Novel

How the García Girls Lost Their Accents is Julia Alvarez’s debut novel, published in 1991, exploring the García family’s relocation from the Dominican Republic to the United States. The semi-autobiographical work reflects Alvarez’s own experiences as an immigrant, blending cultural identity, language, and belonging. The novel’s non-linear structure, composed of 15 interconnected stories, captures the family’s struggles and adaptations across generations. Its vivid portrayal of the immigrant experience resonates deeply, making it a landmark in Latino literature and a poignant exploration of cultural assimilation and identity formation.

Author Julia Alvarez and Her Inspiration

Julia Alvarez, a Dominican-American writer, drew inspiration from her own experiences as an immigrant for How the García Girls Lost Their Accents. Born in New York but raised in the Dominican Republic, Alvarez’s unique cultural duality shaped the novel. Her family’s exile and adaptation to American life influenced the García family’s journey. Alvarez’s work often explores themes of identity, culture, and belonging, reflecting her personal and collective immigrant narratives, making her a prominent voice in contemporary Latino literature.

The Structure and Style of the Novel

The novel features a non-linear narrative, episodic structure, and vignettes, allowing Alvarez to explore themes of identity and cultural adaptation through fragmented, yet cohesive, storytelling.

Non-linear Narrative and Episodic Structure

Alvarez’s novel unfolds through a series of loosely connected vignettes, each capturing pivotal moments in the García sisters’ lives. The non-linear structure mirrors the disjointedness of their cultural experience, jumping forward and backward in time. This episodic approach allows for a mosaic-like portrayal of their journey, emphasizing themes of memory, identity, and the fragmented nature of immigrant life. The structure enhances the emotional depth, offering multiple perspectives on their struggles and adaptations.

Use of Multiple Perspectives and Voices

The novel employs a polyphonic narrative, with each García sister offering unique insights into their shared yet distinct experiences. This multiplicity of voices enriches the storytelling, highlighting individual struggles and collective resilience. By shifting perspectives, Alvarez creates a layered exploration of identity, culture, and belonging. Each voice contributes to the tapestry of their immigrant journey, offering readers a nuanced understanding of the challenges and triumphs faced by the García family in their new American life.

Major Themes in the Novel

Central themes include cultural identity, language barriers, and assimilation, exploring the García sisters’ journey of balancing their Dominican heritage with their new American life experiences.

Cultural Identity and Belonging

The novel delves into the García sisters’ struggle to reconcile their Dominican heritage with their new American identity. Their journey reflects the tension between preserving cultural roots and adapting to a foreign environment. Alvarez explores how the sisters navigate this duality, often feeling caught between two worlds. The loss of their accents symbolizes their gradual assimilation, yet it also underscores their longing for a sense of belonging. This theme resonates deeply, highlighting the universal immigrant experience of balancing tradition and transformation.

Language as a Barrier and a Bridge

Language plays a dual role in the García girls’ lives, serving both as a barrier to assimilation and a bridge to their heritage. Their accents initially mark them as outsiders, creating a divide between their Dominican past and American present. However, as they lose their accents, language becomes a tool for connection and identity formation. Alvarez illustrates how language shapes their experiences, fostering both isolation and unity, and highlighting its transformative power in their journey of self-discovery and cultural adaptation.

Assimilation and Its Challenges

Assimilation into American culture presents significant challenges for the García girls, as they confront cultural differences, language barriers, and societal expectations. Their journey reveals the tension between preserving Dominican traditions and adapting to a new identity. Alvarez vividly portrays the struggles of balancing heritage and assimilation, highlighting the emotional and psychological impact on the sisters. The novel underscores the complexities of shedding accents and cultural traits, illustrating the sacrifices and resilience required to navigate a new world while maintaining their sense of self and belonging.

The García Family and Their Journey

The García family’s migration from the Dominican Republic to America sparks a complex journey of cultural adaptation, identity formation, and generational conflict, shaping their collective and individual futures.

The Sisters’ Adaptation to American Life

The García sisters face unique challenges adapting to American life, navigating cultural differences, language barriers, and identity formation. Each sister’s journey reflects personal struggles and growth, shaped by their Dominican heritage and new surroundings. While they thrive in America, they confront generational conflicts and societal expectations, ultimately finding their own paths to belonging and self-discovery in a foreign land.

Family Dynamics and Generational Conflicts

The García family experiences tension between traditional Dominican values and American influences. Parents cling to cultural roots, while the sisters embrace modernity, leading to clashes. Generational gaps deepen as the girls navigate identity, independence, and loyalty to their heritage. These conflicts highlight the struggles of maintaining cultural identity while adapting to a new world, shaping the family’s collective and individual journeys.

Language and Accent as Metaphors

Accents symbolize cultural blending, with the García girls’ shift from Spanish to accent-free English reflecting their journey from Dominican roots to American identities, blending heritage and adaptation.

The Significance of Losing Accents

Losing their accents symbolizes the García sisters’ gradual assimilation into American culture, reflecting their struggle to balance Dominican heritage with a new identity. The shift from Spanish to flawless English underscores their adaptation to societal expectations, highlighting the emotional cost of cultural blending. This transformation mirrors their journey of self-discovery, where language becomes both a bridge and a barrier, shaping their sense of belonging in a world caught between tradition and modernity.

Language as a Tool for Assimilation

Language plays a pivotal role in the García sisters’ assimilation into American society. Their transition from Spanish to English symbolizes their efforts to fit into a new cultural landscape. Alvarez illustrates how language serves as both a bridge and a barrier, facilitating integration while also creating tension. The sisters’ eventual mastery of English highlights their adaptation, yet it also underscores the loss of their native tongue’s richness, reflecting the broader immigrant experience of sacrifice and transformation in pursuit of belonging.

Critical Reception and Popularity

The novel captivated critics and readers, praised for its poignant portrayal of the immigrant experience, making it a landmark in Latino literature and a popular PDF download.

Impact on Latino Literature

Julia Alvarez’s novel became a landmark in Latino literature, offering a poignant voice to the immigrant experience. Its exploration of cultural identity and language resonated deeply, inspiring future authors and cementing its place as a seminal work in the genre. The book’s success highlighted the importance of diverse narratives, paving the way for more stories about the Latino diaspora and its unique struggles and triumphs in America.

Academic and Literary Analysis

How the García Girls Lost Their Accents has garnered significant academic attention for its nuanced portrayal of identity, culture, and assimilation. Scholars highlight its non-linear narrative and episodic structure, which mirrors the disjointed nature of immigrant experiences. The novel’s exploration of language as both a barrier and a bridge has been extensively analyzed, with critics like Robert C. Evans and M. Matas examining its thematic depth. Its acclaim lies in its ability to resonate with universal themes while maintaining a deeply personal and cultural specificity.

Adaptations and Interpretations

The novel has been adapted into theatrical performances and inspired various interpretations, enriching its cultural impact and reaching broader audiences through diverse artistic expressions.

Theatrical Adaptations and Performances

Julia Alvarez’s novel has been adapted into a theatrical production by Karen Zacarías, capturing the García sisters’ journey with passion and humor. Directed by Antonio Sonera, the play brings to life their struggles and triumphs, blending cultural identity and family dynamics. Performances have been praised for their vibrant cast and sensitive direction, offering audiences a relatable and emotional experience. The adaptation highlights the novel’s universal themes, making it a compelling stage interpretation of the García family’s story.

Media and Cultural References

The novel has been referenced in various media, including a Max Original series and cultural discussions during Hispanic Heritage Month. Its themes of identity and assimilation resonate widely, making it a focal point in conversations about the immigrant experience. The book’s impact extends beyond literature, influencing TV shows and community celebrations, further cementing its relevance in contemporary cultural discourse.

The Immigrant Experience in America

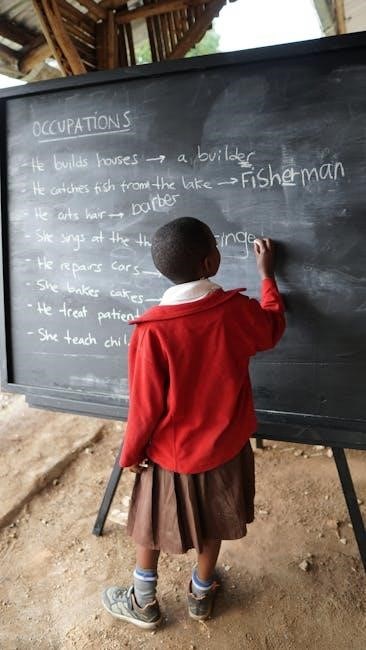

The novel vividly portrays the challenges of adapting to a new culture, highlighting the struggles of identity, language barriers, and cultural differences faced by immigrant families.

Challenges Faced by Immigrants

The García family encounters numerous obstacles, including cultural differences, language barriers, and generational conflicts. Their struggle to balance Dominican traditions with American expectations highlights the universal immigrant experience of adaptation and identity formation. The novel vividly portrays how these challenges impact family dynamics and individual growth, creating a poignant narrative of resilience and transformation in a new cultural landscape.

Identity Formation in a New Culture

The García sisters’ journey reflects the complex process of identity formation in a new culture. As they navigate between Dominican heritage and American life, they struggle to reconcile their dual identities. The novel explores how language, family, and societal expectations shape their sense of self, illustrating the challenges and triumphs of forming a hybrid identity in a multicultural context. This process is marked by both loss and discovery, as the sisters adapt to their new environment while preserving their roots.

How the García Girls Lost Their Accents remains a poignant exploration of identity, culture, and belonging, leaving a lasting impact on contemporary discussions of immigration and heritage.

Legacy of the Novel

How the García Girls Lost Their Accents has left an indelible mark on Latino literature, offering a powerful exploration of identity and assimilation. Its relatable portrayal of the immigrant experience has made it a staple in academic curriculums and book clubs. Adapted into a successful play and referenced in popular culture, the novel continues to resonate with readers, cementing its place as a timeless story of cultural adaptation and self-discovery in America.

Relevance in Contemporary Discussions

The novel remains a vital text in contemporary discussions on immigration and identity, offering insights into the challenges of cultural adaptation. Alvarez’s vivid portrayal of the García sisters’ experiences continues to resonate with today’s diverse readers, making it a cornerstone in discussions about belonging and cultural identity. Its themes of language, family, and assimilation are as relevant now as they were upon its release, ensuring its continued importance in literary and cultural conversations.